Oxygen Free Wafer Curing Oven

As a leading manufacturer of advanced industrial ovens, Sonik are proud to offer our state-of-the-art industrial oxygen free wafer curing ovens, specifically designed to meet the stringent requirements of the semiconductor wafer fabrication industry. These ovens provide unparalleled precision, reliability, and efficiency, ensuring optimal performance in critical manufacturing processes.

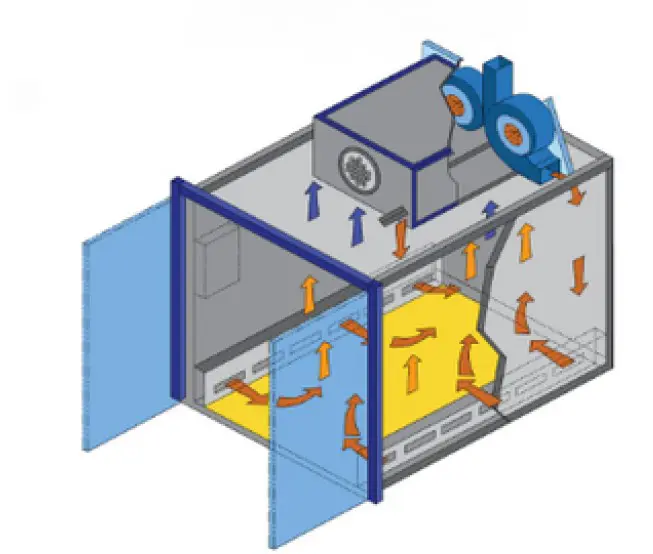

An industrial oxygen free wafer curing oven is a specialized thermal processing unit that utilizes inert gases, such as nitrogen or argon, to create a controlled atmosphere during the heating process. This controlled environment is essential to prevent oxidation and

other undesirable reactions that can compromise the integrity and quality of semiconductor wafers.

Application

In the semiconductor wafer fabrication industry, precision and purity are critical. Ourindustrial inert gas ovens play a vital role in several key processes:

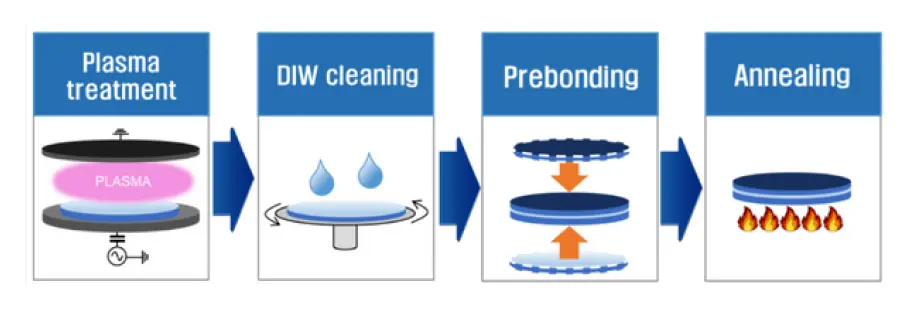

Annealing: During the annealing process, wafers are heated to high temperatures to repairdamage and improve crystal quality. The inert atmosphere prevents oxidation, ensuringthe wafers maintain their integrity and performance

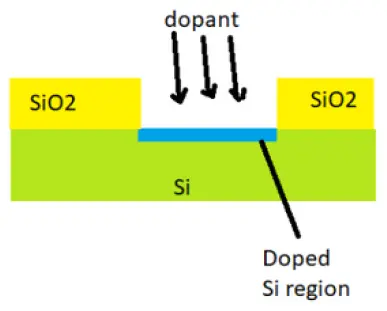

Doping: Doping involves adding impurities to semiconductor wafers to modify theirelectrical properties. Our ovens provide the precise temperature control andcontamination-free environment necessary for successful doping processes.

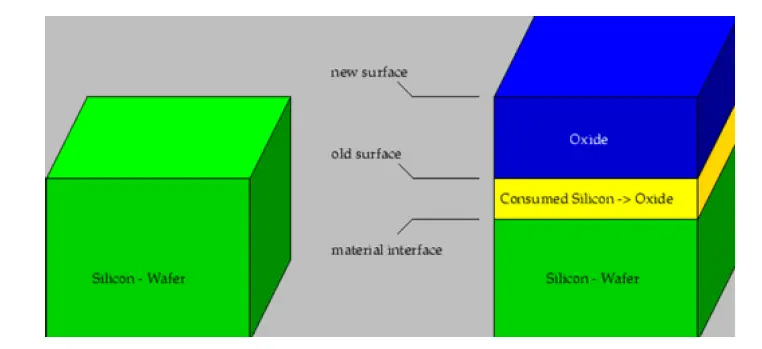

Oxidation Prevention: Many steps in wafer fabrication are sensitive to oxidation. Using an oxygen free atmosphere, our ovens protect wafers from oxidation, which is essential for maintaining the quality and reliability of the final semiconductor products.

Curing and Drying: Photoresist materials and other coatings applied to wafers need to be cured and dried under controlled conditions. Our oxygen free wafer curing ovens ensure these processes occur without introducing contaminants or causing oxidation.

Explore the advantages of our industrial oxygen free wafer curing ovens and discover how we can enhance y our semiconductor wafer fabrication processes. Contact us today to learn more and discuss your specific requirements.

- Fully welded, heavy-duty exterior with reinforced, corrosion-resistant stainless steel.

- Fully automated robust door equipped with horizontal suction suction.

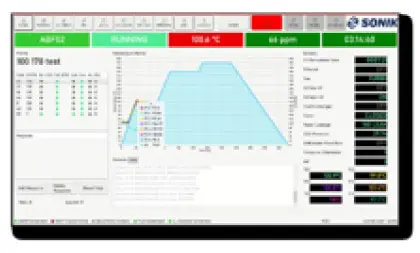

- Real time temperature monitoring system with multi graph display.

- Innovative Recipe Management System streamlines recipe creation, storage, and retrieval for improved efficiency and consistency

efficiency and consistency. - Industrial 4.0 communication protocol ready.

- Cutting edge rapid cooling system that accelerates the cooling process

Comprehensive Safety Features

Certification

System Interface

Overview Page

SECS/GEM Setting

Profile Setting

- Interactive System User Interface with Biosoft touch panel

- SECS/GEM with Recipe Management System (RMS)

- Real time temperature monitoring with graphs display

- Multiple profiles selection

- Alarm triggering for out of range temperature setting

- Monitor supplies flow rate and pressure (N2, CDA, Chill water) and set threshold to trigger alarm

AGV / RGV automation integration

E84 integration with AGV/RGV to achieve lights off production and fully automated shop floor